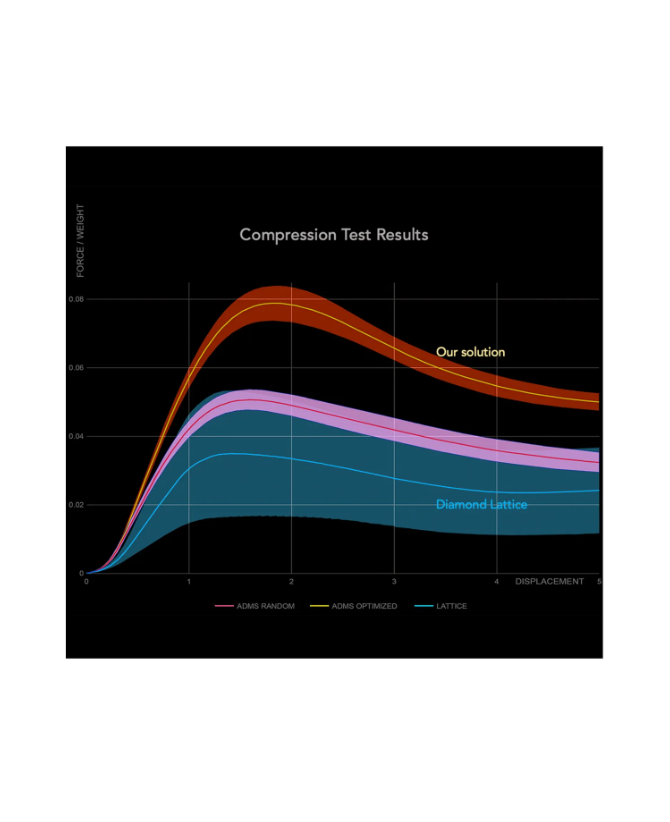

Loadcase Comparison

A performance comparison against well known lattice structures

PROJECT

Topic

SYNOPSIS

ADVANTAGE/BENEFIT

Loadcase comparison

Loadcase

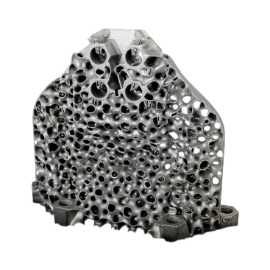

Spherenes have promising performance to optimize structures. As it is hard to make a statement without a validation against current technologies, we compared it against well known lattice structures.

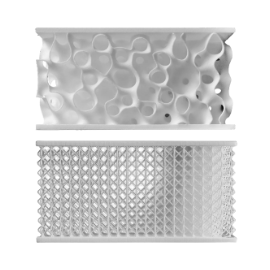

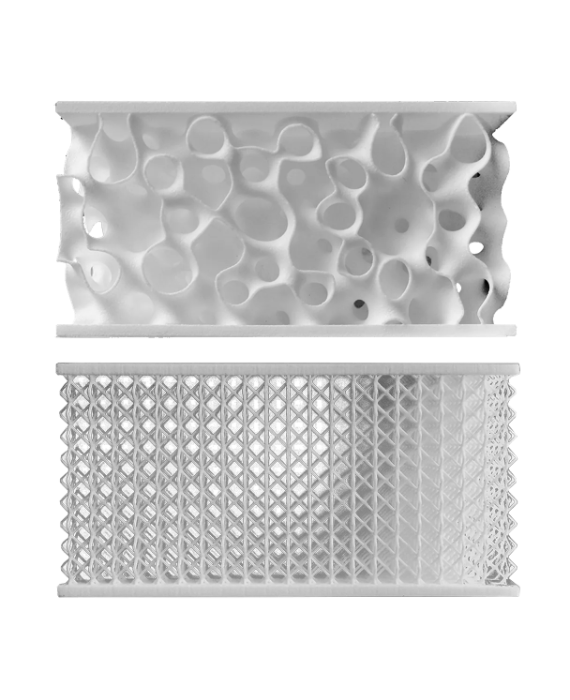

To have independence in our design and testing, a well known swiss engineering firm, Zühlke Engineering, took the challenge to design our competitor for the test.

Superior performance.

Ideal stress distribution.

Let's put it to the test

Spherenes give the opportunity to be optimized for different boundary conditions. The lattice structure also needed to be chosen wisely.

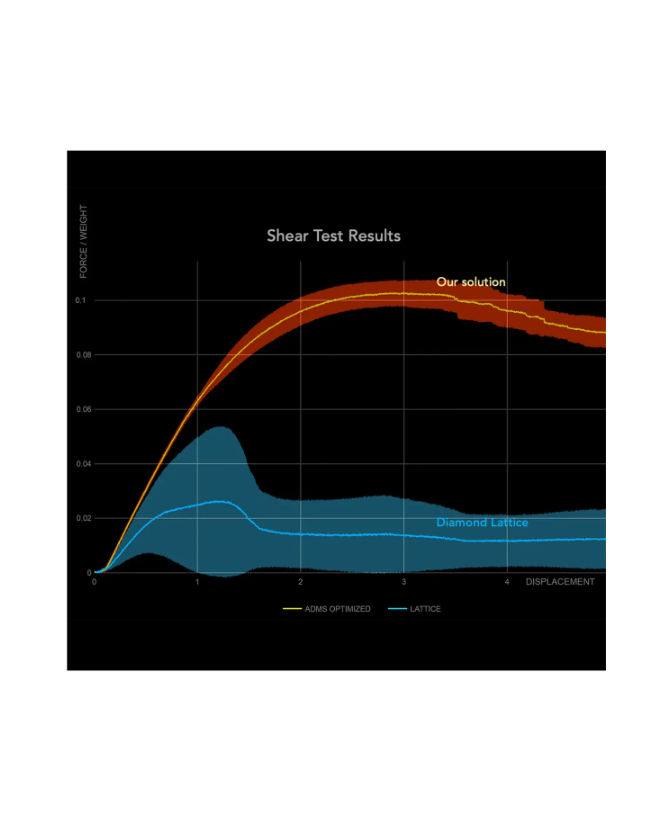

Two load cases were chosen for the comparison: compression (homogeneous) and shear (unhomogeneous).

Fundamental to fair testing was to have similar weight and wall thickness (0.4mm). The testing was based on composite core material testing norms: DIN EN ISO 844 for compression, DIN EN 12090 for shear.

The samples were printed by the same supplier, the tests were performed by a composite testing facility in Berlin.

Shear test

The results shown a superior performance for spherenes. They can be explained with the ideal stress distribution in the structure and the better connection to the solid faces.

As a lattice structure connects point by point, a spherene unite through lines for the solid interface.

Compression test